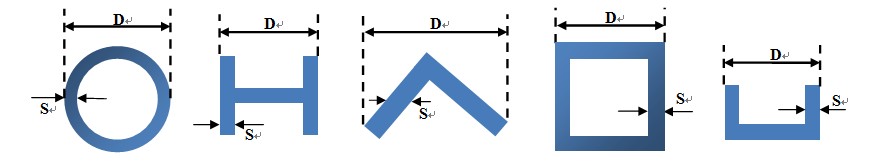

鋸條的選擇,除了切割材料材質(zhì)的影響,工件的形狀、大小也是不容忽視的因素。那對于形狀特殊的管材、型材,該怎么選擇合適的鋸條呢?

除了選擇能有效緩解振動的抗拉齒外,在齒距的選擇上,我們也需要特別注意,以下是我們對不同規(guī)格的管材、型材鋸切的齒距選擇的建議。

管材、型材鋸切的齒距選擇

| (mm) | 管件外徑D (mm) | ||||||||||

| 60 | 80 | 100 | 120 | 150 | 200 | 300 | 400 | 500 | 600 | >700 | |

| 2 | 5/7 | ||||||||||

| 3 | 5/7 | 5/7 | |||||||||

| 4 | 5/7 | 5/7 | 4/6 | 4/6 | 4/6 | ||||||

| 5 | 5/7 | 5/7 | 5/7 | 4/6 | 4/6 | 4/6 | 4/6 | ||||

| 6 | 5/7 | 5/7 | 5/7 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | ||

| 8 | 5/7 | 5/7 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | ||

| 10 | 5/7 | 5/7 | 5/7 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | |

| 12 | 5/7 | 5/7 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 3/4 |

| 15 | 4/6 | 4/6 | 4/6 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | |

| 20 | 4/6 | 4/6 | 3/4 | 3/4 | 3/4 | ||||||

| 30 | 3/4 | 3/4 | 3/4 | 3/4 | |||||||